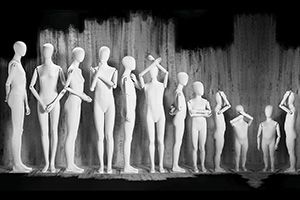

Atrezzo was founded in Barcelona in 1990 with the aim of designing, developing and manufacturing quality visual merchandising products for the global fashion industry.

Our mannequins, completely designed and manufactured in Spain, mix centuries of artisanal tradition with the most advanced techniques in order to provide the best quality, the most innovative materials and a bold design that highlights our clients’ creations.

www.atrezzobarcelona.comIn addition, Atrezzo stands out for its iron-bound commitment to the world of creativity in all its forms, which has led us to collaborate with contemporary artists from all fields.

After many years providing our creations to the most remarkable brands, Atrezzo joined forces with Noa Brands to help building the biggest visual merchandising services company in the world.

We define sustainability as a socio-ecological process characterized by the pursuit of a common ideal: a fair economic development, a great regard for social justice and a special focus on environmental protection.

This document summarizes Atrezzo’s Sustainability Itinerary focusing on the main aspects of our value chain: Made in Spain, Influencers, Production Processes, Commitment, Materials, Delivery and End-of-life

The Sustainability Itinerary is our journey to move closer to our ideal, setting more and more ambitious goals.

Atrezzo’s Philosophy was defined around the concept of local production.

By keeping 100% of our production local, we are generating a direct economic impacts in the local community and we are able to maintain constant surveillance and monitoring labor conditions, ensuring a strict respect of fundamental rights.

Local production ensures the traceability and quality of our products, it minimizes pollution and it ensures respecting deadlines in dispatching orders.

Atrezzo is unique among mannequin competitors: by realizing the whole production in-house, we do not shift responsibility onto other actors of the value chain. This enables Atrezzo to ensure that every impact generated during the production process is properly addressed through its sustainability strategy.

While having always a special focus on environmental protection, we don’t forget our commitment to our most valuable resource: our people. That’s why we ensure the wellbeing and safety of all our workers and strictly respect labor rights in each phase of our value chain.

LSE RESIN

LSE resin is best for high design and product detail, at low production units. The mold is the most adaptable and flexible, allowing for greater product detail.

PU

PU is best for low-quantity production and product resistance. A PU mannequin’s single parts can be easily substituted or upcycled with new pieces and their recyclability degree is quite good (PU mannequins can be shredded and thermally recycled). Moreover, these mannequins require a mold that is highly flexible and, therefore, easily reusable. The cost of PU molds is also low, making this a good material for lower quantity production.

PS

PS uses some recycled inputs and yields a recyclable material. Mannequins made of PS offer a long-term durability and the material can be recycled, so we highly encourage clients to dispose of these mannequins properly at the end of their life.

ADDRESS

C/Girona, 83

08009 Barcelona

Spain

CALL

+34 934 876 164

WEBSITE

www.atrezzobarcelona.com

location